Common Symptoms of Bad TXV Explained

Are you facing issues with the air conditioning system and think you may have a bad TXV? In this guide we are going to explain everything you need to know about symptoms of bad TXV and how to properly diagnose it.

The symptoms of a bad TXV include high superheat, low superheat, high subcooling, low suction pressure and low head pressure. However you might need to take additional diagnostics steps to rule out other factors that can cause similar symptoms

How does a TXV valve work?

For those of us that are behind let me just try to briefly explain what a TXV is. A thermostatic expansion valve (TXV) is a mechanical valve that regulates the amount of refrigerant flowing into the evaporator coil of an HVAC system. It is designed to maintain a specific superheat value by controlling the amount of refrigerant entering the evaporator.

The TXV valve is composed of several components, including a sensing bulb, diaphragm, valve body, and valve seat. The sensing bulb is attached to the suction line of the system, and it measures the temperature of the refrigerant entering the evaporator coil.

What are the symptoms of Bad TXV?

Now that we have an understanding of what a TXV is, what are some of the symptoms to look out for when you suspect you may have a bad TXV?

High superheat

A bad thermostatic expansion valve (TXV) can cause high superheat in an HVAC system by restricting the flow of refrigerant into the evaporator coil. The TXV is responsible for controlling the flow of refrigerant into the evaporator coil based on the temperature and pressure conditions within the coil.

If there are contaminants or moisture in the HVAC system that can get to the TXV and restrict it. This means it may not allow enough refrigerant into the evaporator coil, causing the superheat to increase.

Superheat refers to the temperature of the refrigerant gas leaving the evaporator coil above its boiling point. When the superheat is too high, it indicates that there is not enough refrigerant being evaporated in the coil. This can lead to a decrease in cooling capacity, which can cause the system to run inefficiently.

Low Superheat

A bad thermostatic expansion valve (TXV) can cause low superheat in an HVAC system by allowing too much refrigerant to flow into the evaporator coil.

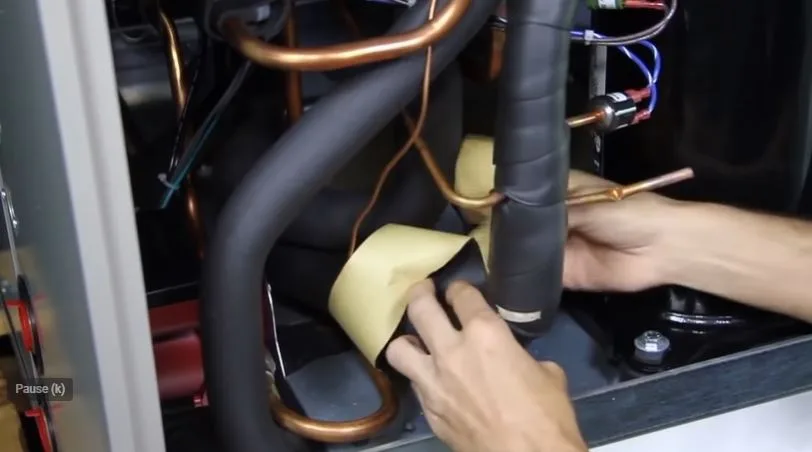

When there are contaminants in the systems, they can cause the TXV to Stick open and allow too much refrigerant to the evaporator. This is also known as overfeeding. Overfeeding could also be caused by poor valve insulation

Overfeeding by TXV can result in too much refrigerant entering the evaporator coil, which can cause the temperature of the refrigerant leaving the coil to drop below the recommended level.

High subcooling

A bad TXV can also cause high subcooling in an HVAC system by restricting the flow of refrigerant into the evaporator coil. Restriction of the TXV caused by either contaminants, moisture of undersized metering device is what may restrict the flow of refrigerant into the evaporator coil too much, which can cause liquid refrigerant to back up in the condenser coil. This can result in a higher than recommended subcooling level, which refers High subcooling

High subcooling can cause reduced cooling capacity and compressor damage, as well as increase the risk of liquid refrigerant flooding the compressor. In addition to a malfunctioning TXV, other factors that can cause high subcooling include a dirty condenser coil or restricted airflow over the condenser.

Low Suction pressure/ low head pressure

A bad TXV can also cause low suction pressure and low head pressure in an HVAC system by restricting the flow of refrigerant into the evaporator coil.

If the TXV is not functioning properly it may restrict the flow of refrigerant into the evaporator coil too much, which can cause a drop in suction pressure as there is not enough refrigerant in the suction line. This, in turn, can cause a drop in head pressure as well, as the compressor is not able to receive enough refrigerant to properly compress and discharge it into the condenser.

Low suction pressure and low head pressure can cause decreased cooling capacity, reduced energy efficiency, and increased wear and tear on the compressor.

TXV failure can also be caused by a rub out on the bulb tube and an external equalizer without a core depressor installed on a port that has a Schrader core in place.

However, despite all symptoms mentioned above, just having any of them does not mean you have a bad TXV. You may need to take additional steps to properly diagnose a TXV valve. We have provides the diagnostics steps and procedure below

How to properly diagnose a TXV valve

- Take refrigerant readings and liquid/suction temperature at both ends on a split system.

- Ensure that there is a full line of liquid before the TXV, with factory specified subcooling of around 10°F.

- Check the subcool outside and confirm that there is no big temperature difference inside to out to rule out kinked lines or plugged line driers.

- Check for enough liquid pressure to have the required pressure differential of at least 100 PSI minimum difference between liquid line pressure and the desired evaporator pressure.

- Low head pressure due to low ambient conditions can impact the ability of the valve to do its job.

- Check the superheat at the end of the evaporator and ensure that it is maintaining 6-14°F at the evaporator outlet.

- If superheat is lower than 6°F, it could be overfeeding; if well above 14°F, then it’s a failed closed (underfeeding) valve.

- Keep in mind that some valves may have a screen right before the valve that can be the cause of the restriction rather than the valve itself.

- Intentionally freeze the coil or use thermal imaging to spot if it’s the valve or the screen causing the issue.

- The TXV is designed to maintain a fairly fixed superheat, so finding the point of temperature drop can help diagnose the problem.

Final thoughts

In conclusion, a TXV valve plays a crucial role in maintaining the proper flow of refrigerant and ensuring efficient operation of HVAC systems. Identifying the symptoms of a bad TXV and addressing the issue promptly can save money on energy bills and prevent costly system failures.

Timely regular maintenance can help prevent TXV valve issues and keep HVAC systems running smoothly.

More resources

https://www.achrnews.com/articles/142410-how-to-diagnose-a-thermostatic-expansion-valve-failure

![What Is Amazon Thermostat Delayed Start? [And How to Fix it]](https://thermostating.com/wp-content/uploads/2023/03/Amazon-thermostat-jpg.webp)

![Nest Thermostat Blowing Hot Air On Cool [Easy Fix]](https://thermostating.com/wp-content/uploads/2023/01/nest-set-to-73-768x415.webp)

![Honeywell Thermostat Not Showing Heat Option [Fixed]](https://thermostating.com/wp-content/uploads/2023/02/honeywell-thermostat-pro-series-thermostat.png)